Sample Text

RMZ Oilfield was established in Singapore since July 2009, by a team of oilfield experts with respective experiences in providing “complete solution for oilfield industry”. RMZ is a Singapore based company specialized in design and manufacturing of oilfield equipment and service provider.

We focused our business in Designing and Manufacturing of Oilfield Products. Our specialization is in Wellhead Pressure Control & Flow Control Equipment Completion Products, Wire-line Tools and Coiled Tubing Tools, Sub Sea Products, Recertification and Rental Services.

The main motivation when establishing the company is to provide “complete solution for oilfield industry” with highest quality, safety and reliability. We are proud to say that our employees are some of the best experts in the field of development oilfield equipment with extensive design and manufacturing knowledge.

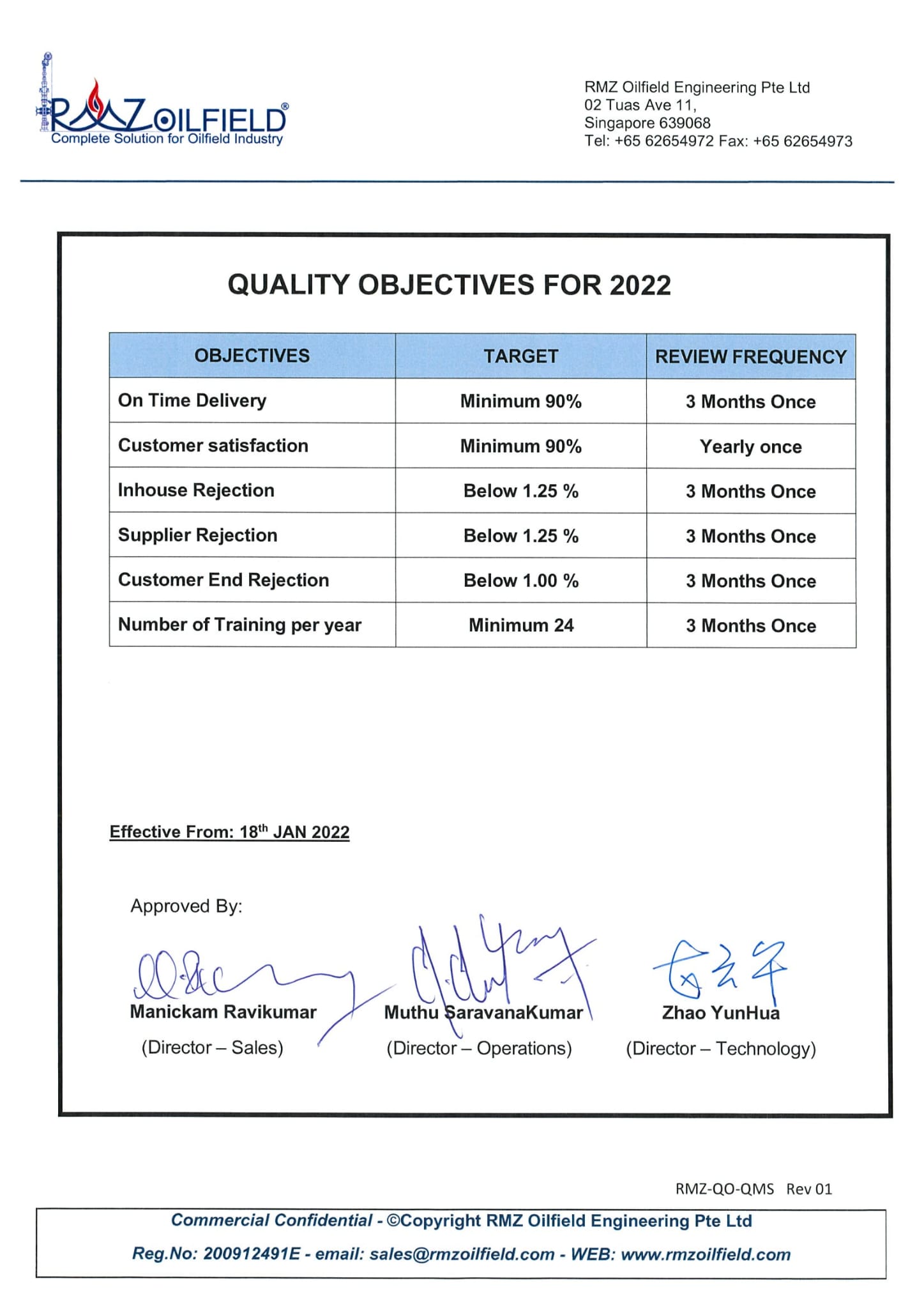

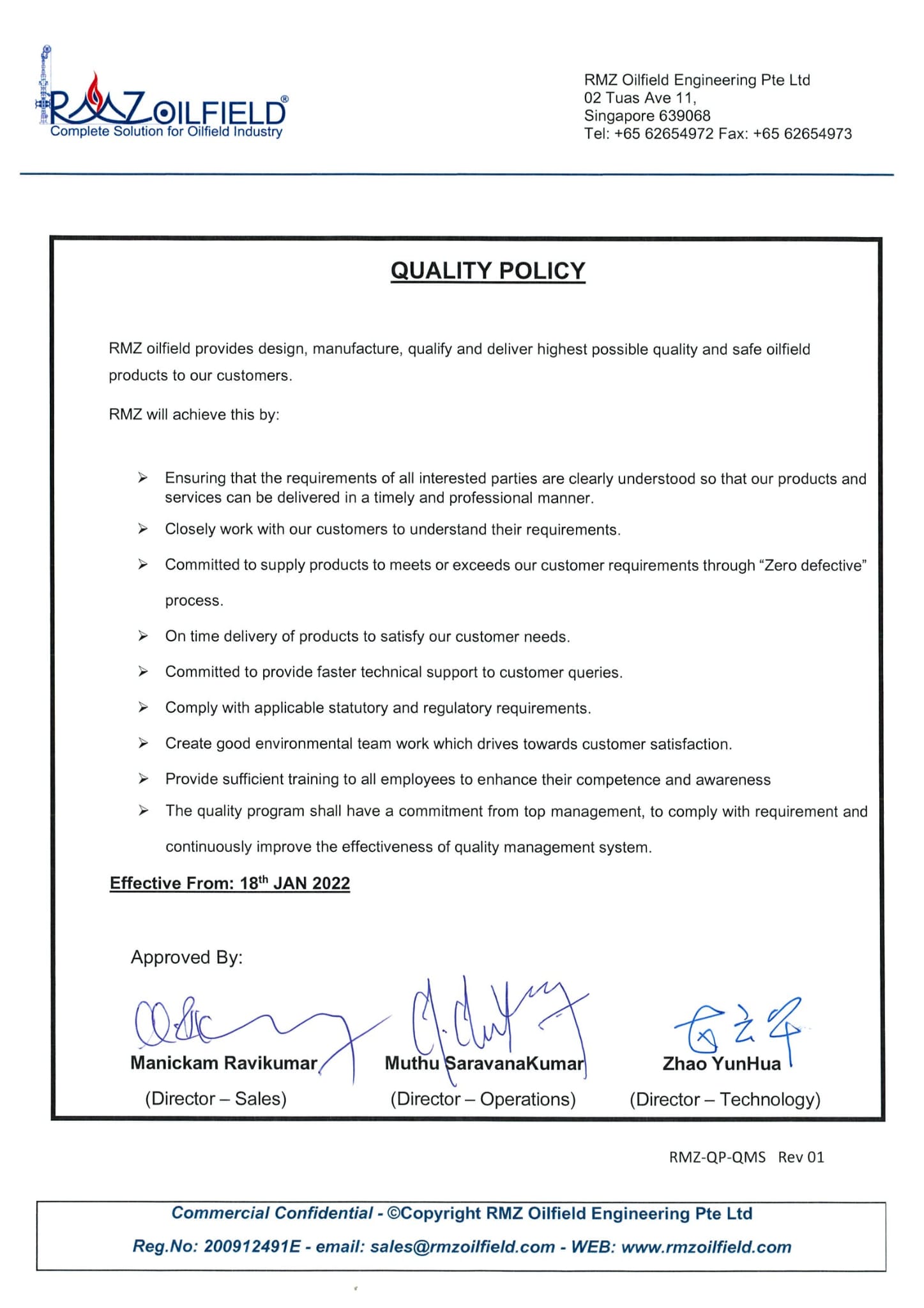

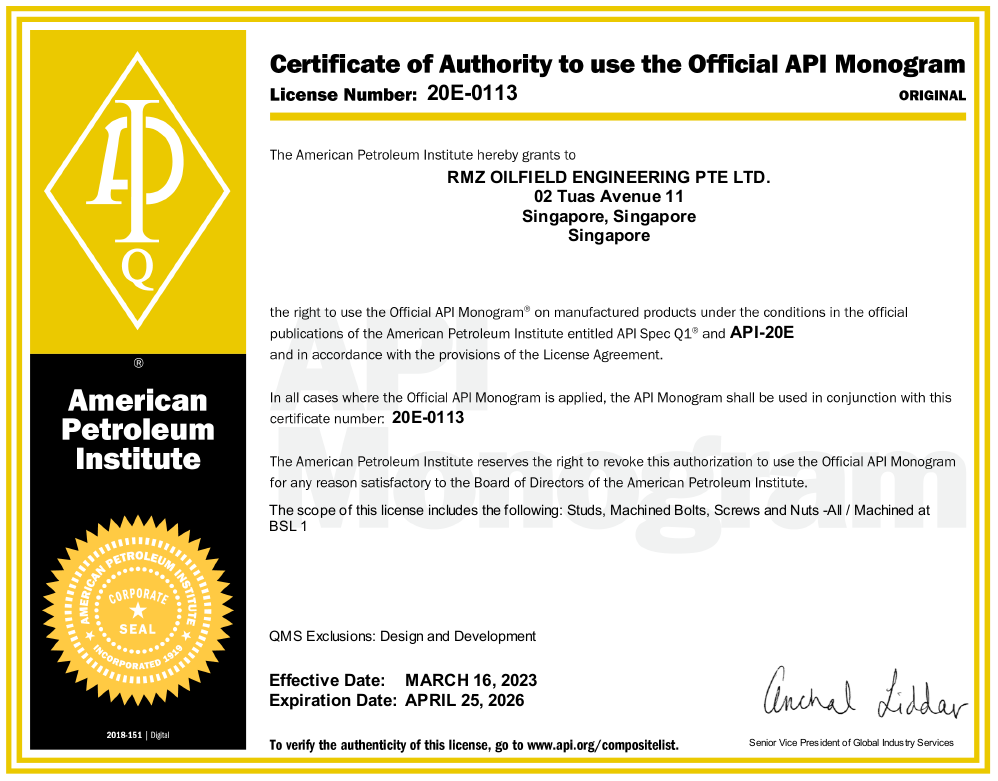

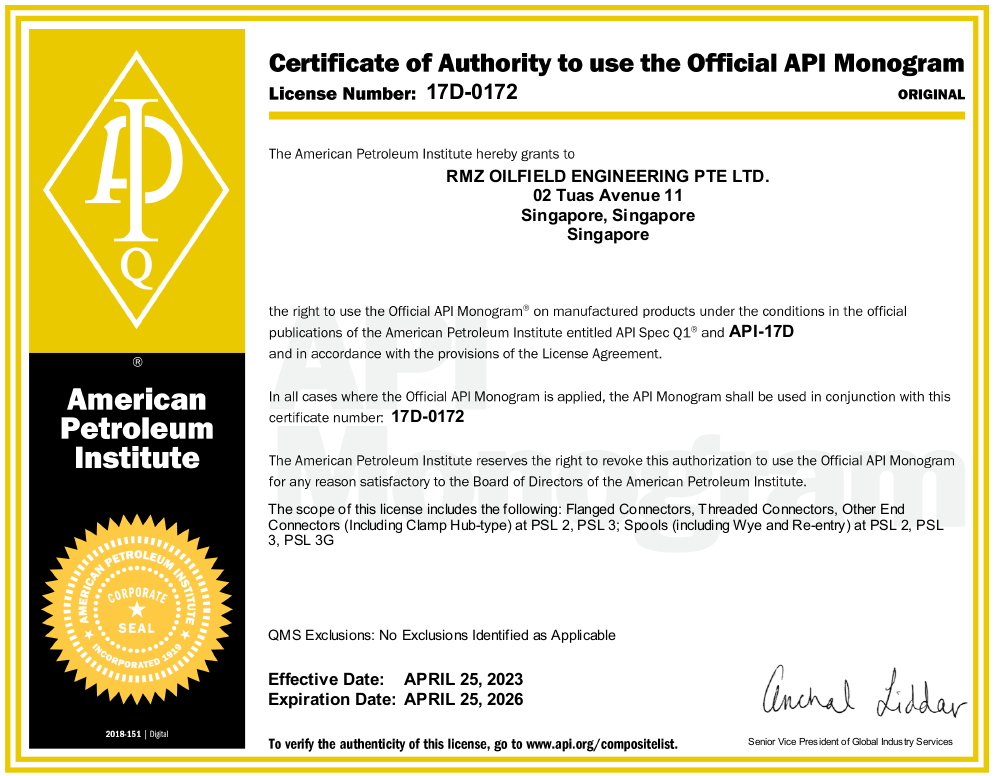

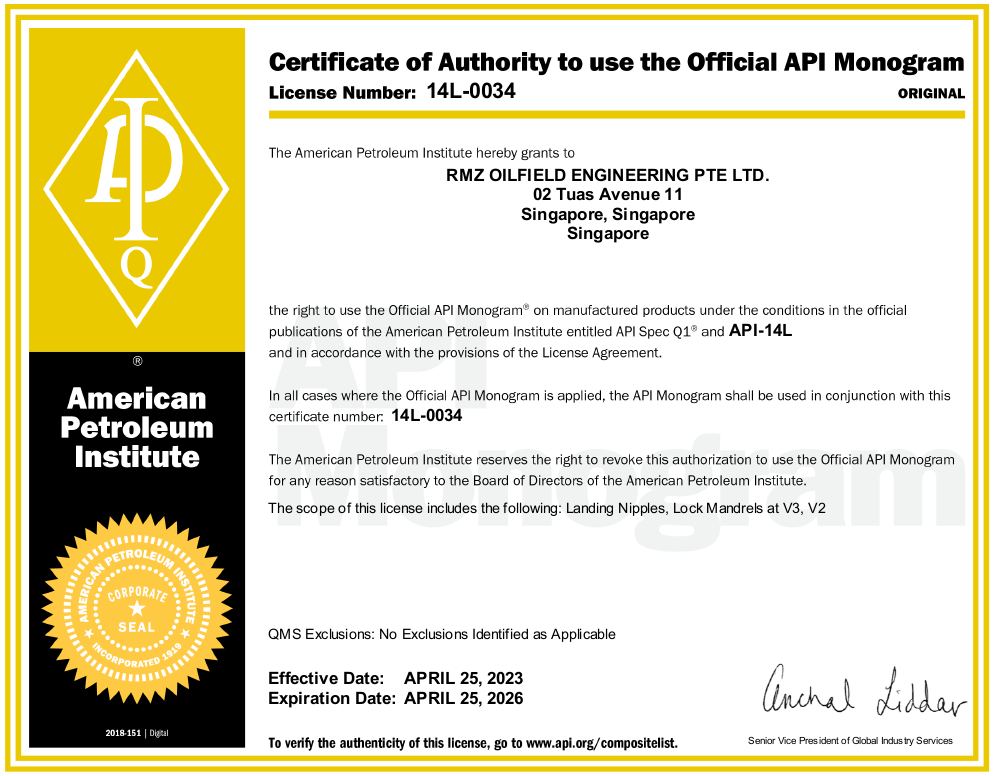

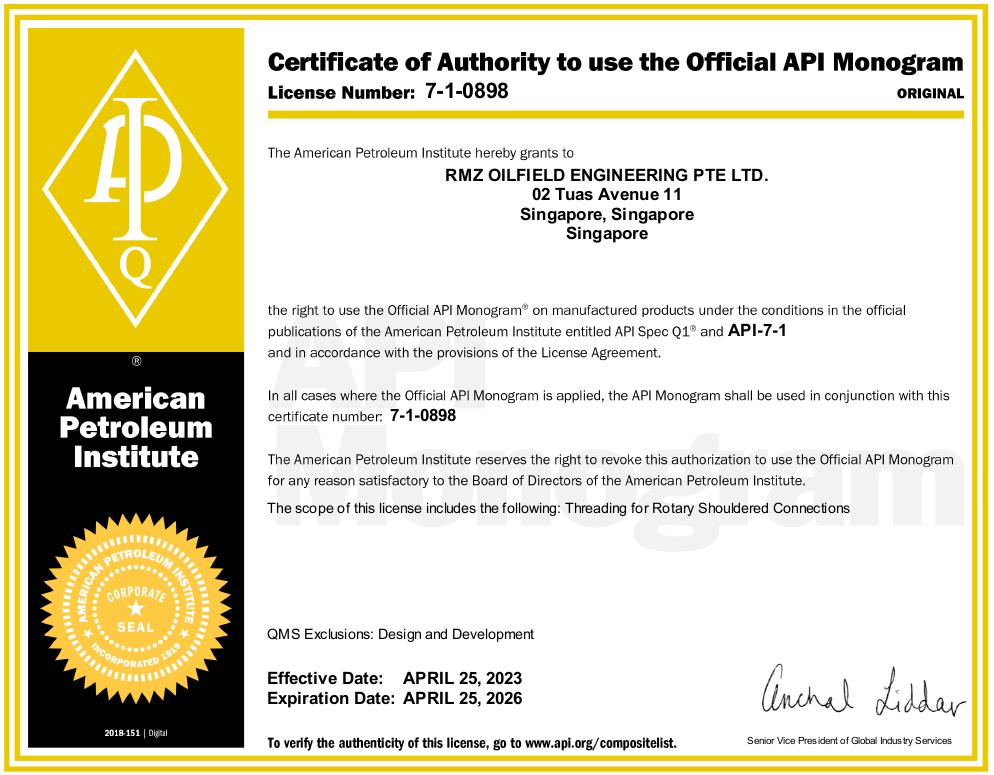

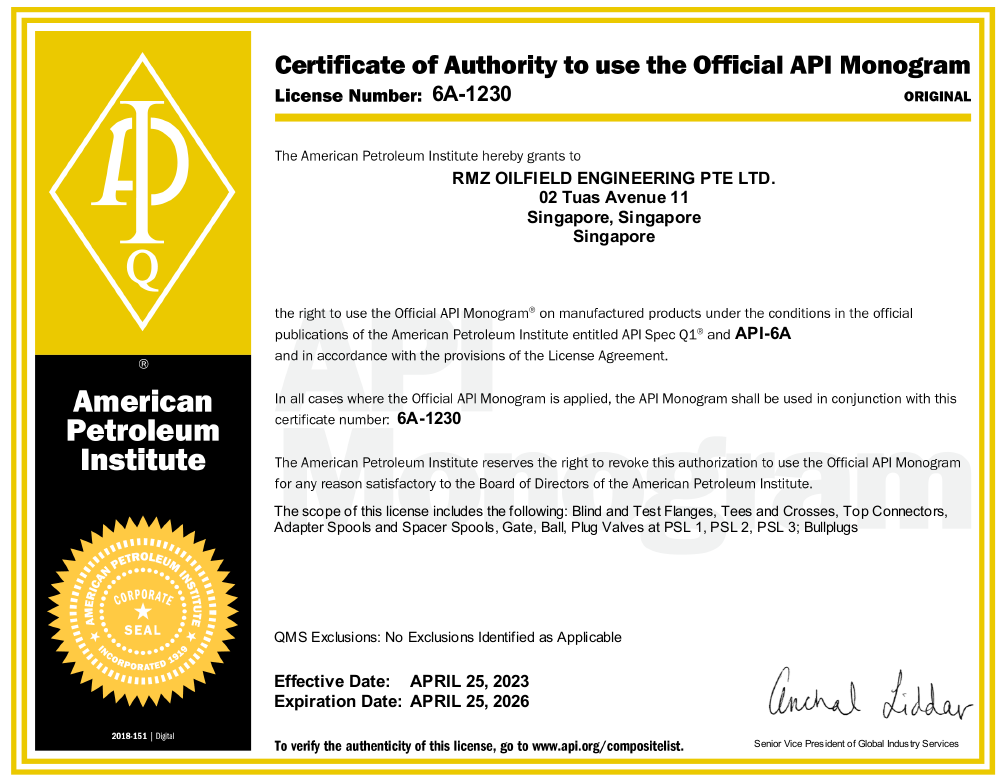

RMZ maintains a documented quality management system designed and implemented to meet the requirements of ISO9001:2015 and API specification Q1 9th Edition. This system identifies and defines the processed needed for the quality management system and controls of those processes, thus providing our customers with highest confidence that the design, manufacture and servicing of RMZ products are performed in a well-defined and controlled environment.

RMZ Oilfield has a duty of care to all employees, contractors, visitors and environment to provide a safe and healthy environment. RMZ is ISO 9001:2015, ISO 45001: 2018 & ISO 14001:2015 certified company and safety is the core business of the company.

RMZ Mission is achieving greatest value by providing tailored and outstanding oilfield products with committed quality to our valuable customers, that helps to improve efficiency and productivity which leads to greatest success of our customers.

RMZ vision is a world class oil and gas equipment solution provider with committed technology and high quality through continual improvement approach and provision of unique working environment and culture.

© 2019 All Rights Reserved by RMZ Oilfield Engineering Pte Ltd.