Contact Information

RMZ Oilfield Engineering Pte Ltd

02 Tuas Ave 11Singapore – 638985

+(65) 6265 4972

sales@rmzoilfield.com

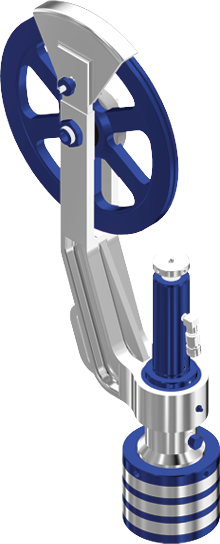

The RMZ Hydraulic Wireline Stuffing Box is used when it is necessary to perform wireline work under well pressure. The sheave assembly allows the line to be guided from the wireline unit and through the Stuffing Box Body. Slickline is passed over the sheave wheel and down through a hydraulic packing stack within the stuffing box body. Upper and lower bushing are provided to ensure that the slickline is guided into the centre of the packing stack.

The hydraulic packing stack can be compressed from a safe distance should the packing leak due to wear.

Internal component that are in contact with the wire are manufactured from brass. A ball check valve is provided to prevent the escape of well fluids in the event of the slickline breaking.

• Contain well pressure whilst the slickline is either moving or stationary.

• Upper and lower bushing ensures accurate alignment into the centre of the packing stack.

• Brass internal components prevent slickline damage.

• Light weight and reliable.

• Elastomers options available to suite specific applications.

• Sheave wheel available with 16”, 20” diameter.

• Available for all slickline wire sizes

• Available in 5,000, 10,000 & 15,000 psi working pressure.

• Available with any Combination of Quick Unions.

• Available in H2S & Standard service.

• Customizable to meet customer requirement.

• Bottom Connection, wire size, Sheave Wheel size details.

• Pressuring rating, Service, Temperature class, Product specification level.

Technical Specification

| CONNECTION | PRESSURE RATING (PSI) | SVC | SIZE OF CATCH FISH | P/N |

|---|---|---|---|---|

| 5.75″-4AC (4.00″ SEAL) ‘O’ QUN | 10,000 | H2S | 1.187″ ~ 2.312″ | 990038529 |

| 6.125″-4x2AC (4.75″ SEAL) QUN | 10,000 | H2S | 1.187″ ~ 2.312 | 990038539 |

| 7.875″-4x2AC (6.125″ SEAL) QUN | 10,000 | H2S | 1.187″ ~ 2.312″ | 990044517 |

NOTE:

1. All surface pressure control equipment is manufactured and certified to API6A, SI1996/913 and NACE MR-01-75 (for H2S rated equipment). This equipment comes with full certification / Documentation, Operational / maintenance Procedure, Aluminium thread protectors and is painted to client colour specification.