Contact Information

RMZ Oilfield Engineering Pte Ltd

02 Tuas Ave 11Singapore – 638985

+(65) 6265 4972

sales@rmzoilfield.com

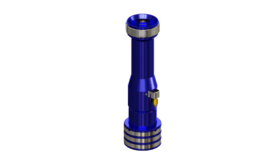

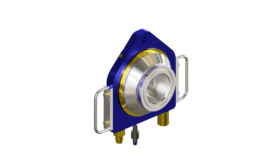

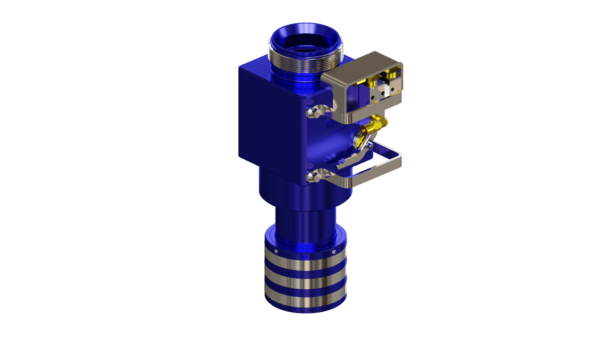

The RMZ Tool Trap is designed to stop wireline tools from falling back down the well should the wireline accidently break at the Rope Socket when pulling back into the Lubricator. Hydraulic actuation is required to open the flappers prior to running downhole. Once the toolstring has passed; the sleeve is returned hydraulically to its first position, allowing the flappers to close. When returning to the lubricator, the flappers automatically hinge open to receive the toolstring from falling down hole.

Tool traps are manufactured with quick unions for easy installation within the Lubricator Package.

• Positive tool passage indicator.

• Pressure-balanced flapper shaft.

• Single piece flapper accept tool weight from above.

• Small hydraulic chamber allowing efficient hand pump operation.

• Enhanced safety.

• Single flapper for all wire size.

• Hydraulic or Manually operated flapper available. Hydraulic is default.

• Available in 5,000, 10,000 & 15,000 psi working pressure.

• Available with any Combination of Quick Unions.

• Available in H2S & Standard service.

• Customizable to meet customer requirement.

• Connection, manual or hydraulic operated flapper.

• Pressuring rating, Service, Temperature class, Product specification level.

Technical Specification

| CONNECTION | PRESSURE RATING (PSI) | SVC | ID | TYPE | P/N |

|---|---|---|---|---|---|

| 5.00″-4AC (3.50″SEAL) ‘O’ QUN | 5,000 | H2S | 3.00″ | MANUAL | 990057121 |

| 6.125″-4x2AC (4.75″ SEAL) QUN | 10,000 | H2S | 4.06″ | HYDRAULIC | 990024837 |

NOTE:

1. All surface pressure control equipment is manufactured and certified to API6A, SI1996/913 and NACE MR-01-75 (for H2S rated equipment). This equipment comes with full certification / Documentation, Operational / maintenance Procedure, Aluminium thread protectors and is painted to client colour specification.