Contact Information

RMZ Oilfield Engineering Pte Ltd

02 Tuas Ave 11Singapore – 638985

+(65) 6265 4972

sales@rmzoilfield.com

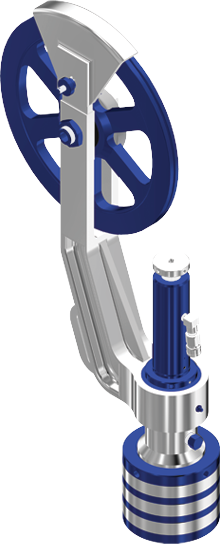

The RMZ Rapid Load Stuffing Box was designed to overcome the manual handling Problems caused by the Heavy Weight of Standard Stuffing Box.

Leaving the heavier main body part of the stuffing box connected to the upper lubricator and designing a separate packing cartridge as the only part that needs moving, has resolved the manual-handling problem. A conventional stuffing box can weigh 50kg or more, however the removed packing cartridge weighs in at only 14kg. A rope socket can be made up in this packing cartridge and loaded into the lubricator rig-up from the top.

To allow the packing cartridge to be inserted or removed, the sheave bracket assembly pivots out of the way. As it does so, a cam device lifts three brass retainer roller away from the sheave wheel, simplifying the loading of wire. When returned to position, the rollers provide the most secure wire retention possible. The packing cartridge itself carries four additional rollers to ensure that the wire is perfectly centered at all times, minimising wear on the hydraulic piston, packing glands, packing and of course, the wire itself. The packing is larger than in a conventional stuffing box, resulting in improved sealing and wear characteristics. This is particularly significant as bigger slicklines become more common. To avoid damaging expensive slicklines, internal components that come in contact with the wire are manufactured from brass.

Within the packing cartridge is an integral velocity ball check valve, which prevents the escape of well fluids in the event of the slickline breaking. Additionally, the assembly has an integral injection oil bath facility. To compliment the conventional packing cartridge set up, additional clip-on modules can be supplied to provide a chemical injection. There is a hydraulic pack off built into the top of the cartridge to allow compression of the packing from a safe distance should they start to leak due to wear.

• Separate light packing cartridge eliminates the traditional fitment of the stuffing box where line damage and manual handling issues can occur lifting a one piece heavy stuffing box to the lubricator

• A cam device simplifies the loading of wire onto the sheave

• Packing cartridge contains four rollers to ensure wires are tracked accurately

• Integral velocity ball check value preventing the escape of well fluids

• Overcomes the handling problem of increased weight.

• Reduces the weight by 30%

• Rollers offer secure wire retention and minimise wear

• Assembly supplied with load test certificate.

• Bottom Connection, wire size, Sheave Wheel size details.

• Pressuring rating, Service, Temperature class, Product specification level.

NOTE:

1. All surface pressure control equipment is manufactured and certified to API6A, SI1996/913 and NACE MR-01-75 (for H2S rated equipment). This equipment comes with full certification / Documentation, Operational / maintenance Procedure, Aluminium thread protectors and is painted to client colour specification.