Contact Information

RMZ Oilfield Engineering Pte Ltd

02 Tuas Ave 11Singapore – 638985

+(65) 6265 4972

sales@rmzoilfield.com

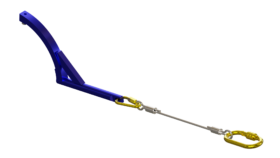

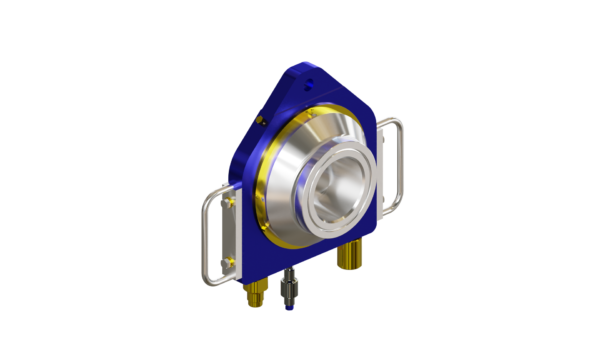

The RMZ Turnaround Sheave has been specially designed to reduce the overall height of the pressure equipment string.

With the conventional pressure equipment system the top sheave is positioned above the tool catcher, grease injection control head and line wiper. By installing the sheave inside a pressure retaining chamber and connecting one end to the tool catcher, the grease injection control head and line wiper can be connected vertically downward, thus reducing the overall height of the system.

The design of the Turnaround Sheave allows the operator to utilise existing equipment (grease injection control heads and line wipers), eliminating the need to purchase all new items. Notice that the Turn Around Sheave must be secured to a member rated 2 x maximum line pull (similar to a wireline top sheave) and cannot be used unsupported.

• Sheave come with range of size 16”, 18”

• Available in 5,000 psi, 10,000 psi working Pressure.

• Available in H2S & Standard Service.

• Connection details, pressure rating, service, temperature class, product specification level

• Sheave size, wire size, safe working load.

Technical Specification

| SHEAVE SIZE | CONNECTION | SVC | PRESSURE RATING (PSI) | SWL | WIRE SIZE | P/N |

|---|---|---|---|---|---|---|

| 16″ | 2.00″-10 AC | H2S | 10,000 | 13.5 TONS | 3/16″ | 990052262 |

| 16″ | 2.00″-10 AC | H2S | 10,000 | 13.5 TONS | 7/32″ | 990050614 |

| 16″ | 2.00″-10 AC | H2S | 10,000 | 13.5 TONS | 1/4″ | 990052263 |

| 16″ | 2.00″-10 AC | H2S | 10,000 | 13.5 TONS | 5/16″ | 990052264 |

| 16″ | 2.00″-10 AC | H2S | 10,000 | 13.5 TONS | 9/32″ | 990052265 |

| 16″ | 2.00″-10 AC | H2S | 10,000 | 13.5 TONS | 7/16″ | 990052291 |

| 16″ | 2.00″-10 AC | H2S | 10,000 | 13.5 TONS | 15/32″ | 990052292 |

NOTE:

1. All surface pressure control equipment is manufactured and certified to API6A, SI1996/913 and NACE MR-01-75 (for H2S rated equipment). This equipment comes with full certification / Documentation, Operational / maintenance Procedure, Aluminium thread protectors and is painted to client colour specification.

2. The information in the table is given as a guide only, as the information may change depending on the Quick Unions used.